Xanthan gum is a pentasaccharide repeating unit composed of D-glucose, D-mannose, D-glucuronic acid, acetic acid and pyruvate. The molar ratio of glucose, mannose, and glucuronic acid is 2.8:3.0:2.0. Xanthan gum is produced from fermentation medium containing sugars (such as glucose, sucrose, starch, hydrolyzed starch, etc.) in the presence of a suitable nitrogen source, dipotassium hydrogen phosphate and appropriate trace elements. Strains function, fermentation, and then after extraction, drying, crushing and other procedures.

Xanthan gum is tasteless, odorless, non-toxic, safe to eat, and easily soluble in water. It presents polyanions in aqueous solution and has unique physical and chemical properties. In industrial production, it is mainly used as a thickener, but also as a suspending agent, emulsifier, and stabilizer. So far, xanthan gum is considered to be the most superior biological glue in the world. It is widely used in food, fruit juice, beverage, feed, cosmetics, medicine, ceramics, fire protection, petroleum and other industries. Its market growth potential exceeds all Hydrophilic glue. This article reviews the structure, properties and production of xanthan gum, and describes the application of xanthan gum in the food industry.

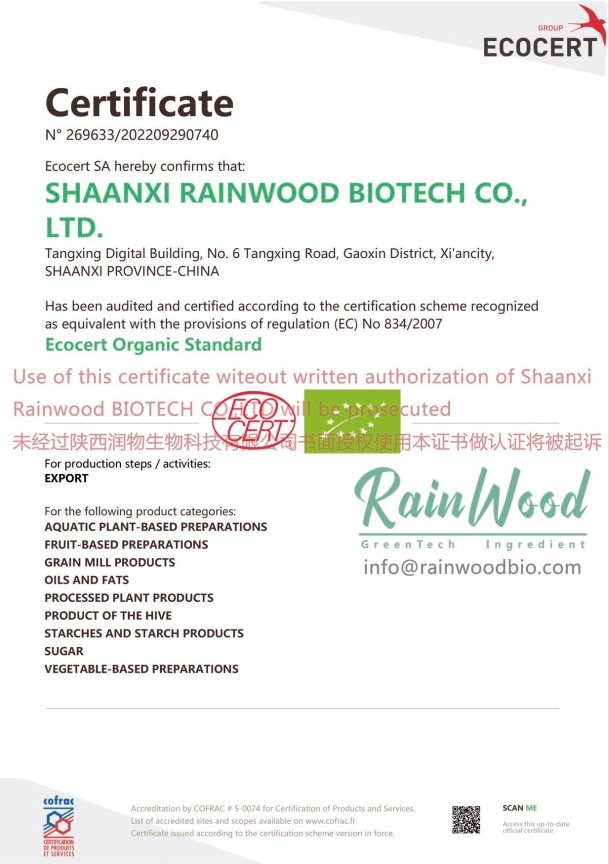

Shaanxi Rainwood Biotech Co., Ltd. have professional production of Xanthan gum and other products for 15 years, is recognized as a professional plant extract manufacturers

Structure

Xanthan gum is a light white or light beige powder composed of repeated five sugar units. Its main chain is the same as that of cellulose, that is, it is composed of glucose connected by β~1,4 glycosidic bonds, and three connected monosaccharides are composed of Side chain: mannose-glucose-mannose. The mannose connected to the main chain is usually modified by an acetyl group. The mannose at the end of the side chain undergoes an acetal reaction with pyruvate to be modified, while the glucose in the middle is oxidized to glucuronic acid. Xanthan gum has a regular primary structure as well as a secondary structure. According to X-ray diffraction and electron microscopy, the molecules of xanthan gum form a regular helical structure by hydrogen bonding. The double helix structure relies on the weak force to form a three-dimensional network structure, which is the tertiary structure of xanthan gum, which exists in the form of liquid crystal in the aqueous solution.

Nature

Xanthan gum is known as \”industrial monosodium glutamate\” and is currently the world\’s largest-scale and most widely-used microbial polysaccharide. It mainly has the following properties.

(1) Xanthan gum is tasteless, odorless, and has strong application safety. It has a high viscosity. The viscosity of 1% aqueous solution is 100 times that of gelatin, so it can be used as a good thickening and stabilizer.

(3) Unique rheology. Under shearing action, the viscosity of the solution will drop rapidly. Once the shearing action is relieved, the viscosity of the solution will be restored immediately. This characteristic gives foods such as ice cream, ham, fruit juice and vegetable protein. Beverages and baked goods have a good taste. This characteristic also makes xanthan gum widely used in petroleum drilling and exploitation.

(4) Good thermal stability, maintaining unique functions in a larger temperature range (-18-130°C), and is a good auxiliary material for the production of frozen foods and baked foods.

(5) Acid-base stability, its viscosity is basically not affected by acid-base, and can maintain the original characteristics within the range of PH value of 1-12, so that it has a wide range of applications.

(6) It has strong anti-oxidation and anti-enzymatic effects, even in the presence of sodium hypochlorite, hydrogen peroxide, and biologically active enzymes.

(7) It has wide compatibility. Mixtures with guar gum and locust bean gum can produce beneficial synergistic effects. This kind of structural glue can produce gel effect under certain conditions.

(8) When coexisting with high-concentration salts and sugars, it still maintains a stable thickening system.

(9) It has good suspension for insoluble solid particles and oil droplets.

(10) Microwave stability. The stable system that has been formed will not affect its performance even if it is frozen or thawed in a microwave oven.

(11) Good compatibility with salts, acids and bases, and good reactivity with galactomannan.

Production

Xanthan gum-producing strains: Xanthan gum-producing strains belong to several species of Xanthomonas. At present, the strains used in industrial production are mainly Xanthomonas black rot in cabbage, in addition to Xanthomonas vulgaris and Xanthomonas mallow Bacteria and carrot xanthomonas can also be used as fermentation bacteria.

The figure below is a simplified diagram of the production process of xanthan gum. The production of xanthan gum is affected by the composition of the medium, the conditions of the medium (temperature, pH, dissolved oxygen, etc.), reactor type, operation mode (continuous or intermittent), etc. The influence of many factors. The strain can grow at 25°C to 30°C, and the optimum fermentation temperature is 28°C. Researchers have put forward a specific equation for the relationship between temperature and growth rate.

Extraction of xanthan gum: In comparison, the cost of recovering products from fermentation broth is higher. Generally, the components in the final fermentation broth are: xanthan gum: 10-30L, cells: 1-10g/L, residual nutrients 3-10L, and other metabolites. Due to the presence of high concentration of xanthan gum, the solution concentration is very large, which increases the difficulty of the extraction operation. Therefore, it is advisable to do the dilution treatment first. The main steps of extraction include precipitation of cells, precipitation, dehydration, drying, and grinding of xanthan gum.

Shaanxi Rainwood Biotech Co., Ltd. is committed to the research and development of plant extracts. It has more than 15 years of experience in the export of plant extracts and has passed the ISO9001, ISO 22000, KOSHER, HALA organic certification. You will get the cheapest price and best quality from us, welcome to inquire.

Application in food

Xanthan gum has been accepted by many countries as a food additive. It has become an important stabilizer, suspending agent, emulsifier, thickener, binder, and processing material with high added value and high quality in the fields of beverages, cakes, jelly, canned food, seafood and meat products processing. It can be summarized as the following aspects.

1) Acid and salt-tolerant food thickening stabilizer

It is used in various foods such as fruit juice drinks, concentrated fruit juices, and seasonings (such as soy sauce, oyster sauce, salad dressing). The stabilizing effect of xanthan gum is significantly better than other gums, and it has strong thermal stability. General high-temperature sterilization will not affect it. It can be used in various fruit juice drinks, pulp drinks, vegetable protein drinks, etc., with a dosage of 0.08-0.3 . Xanthan gum\’s excellent salt resistance, acid and alkali resistance can completely replace the traditional thickener starch in soy sauce. It can overcome the shortcomings of starch precipitation, and can make soy sauce fine and uniform, improve wall-hanging and coloring properties, and extend shelf life . For flavored sauces such as jam and bean sauce, xanthan gum is used as a thickening stabilizer to make the sauce uniform, good mixing, non-caking, easy to fill, and improve the taste.

2) Food emulsifier

Used as an emulsifier in various protein beverages and milk beverages to prevent oily water layer and improve protein stability, prevent protein precipitation, and also use its emulsifying ability as a foaming agent and foam stabilizer, such as beer manufacturing, etc. . After adding 0.02% xanthan gum to the emulsification system based on legume protein, the emulsification is obviously improved, and the mixed system has high shear rate and heat-induced high viscosity characteristics.

3) Food filler

As a stable high-viscosity filler, it can be widely used in the processing of various types of snacks, bread, biscuits, candies and other foods. Without changing the traditional flavor of the food, the food has better shape retention and longer The shelf life and better taste are conducive to the diversification and industrial scale production of these foods. In the production of various frozen foods, xanthan gum has the functions of preventing its loss of water, delaying aging, and extending the shelf life.

4) Food emulsion stabilizer

Used as an emulsion stabilizer in frozen foods. In ice cream and ice cream, xanthan gum can adjust the viscosity of the mixture, so that it has a uniform and stable composition, and the tissue is soft and soft. Due to the relationship between the viscosity of xanthan gum and temperature, it has plasticity and shear Therefore, the viscosity decreases and the resistance decreases during the processing operation, which is beneficial to the process. During the cooling and aging stage, the viscosity recovers, which is beneficial to increase the expansion rate, prevent the formation of large ice crystals in the ice cream tissue, and make the ice cream smooth and delicate. At the same time, the freeze-thaw stability of the product is improved, and the cream and water are evenly mixed during melting, and no slurry separation phenomenon occurs. The general aging time is 2~3h. The dosage is 0.2% to 0.4%.

5) Food adhesive

Xanthan gum can cross-link some water-soluble powder substances, such as sodium alginate, casein, methyl cellulose and polyethylene glycol cellulose sodium salt, to make a binder. This adhesive is used in food processing to improve texture and increase film-forming properties. This property of xanthan gum can be used to make granular pastes. Compared with traditional pastes, pastes made of xanthan gum have low dispersibility, high uniformity and solubility, good fluidity and filling performance, and excellent solid storage properties due to non-cohesiveness.

6) Application of xanthan gum in specific food processing

①The influence of xanthan gum on the quality of noodles

(1) The formation of gluten by xanthan gum tends to strengthen first and then weaken, and its influence on water holding capacity will affect other gluten indicators.

(2) Xanthan gum has a better effect on improving the silty properties, but has a weakening effect on the tensile properties.

(3) Xanthan gum has little effect on the swelling potential of starch, and regularly decreases the initial gelatinization temperature of flour. The peak viscosity is the largest when the amount of colloid is 0.2.

(4) Xanthan gum has a very good improvement in cooking characteristics. As the proportion of colloid increases, various indexes of cooking characteristics decrease.

(5) The addition of colloid increases the hardness, adhesiveness and chewiness of the texture of the noodles, while the adhesiveness and elasticity, cohesiveness and recovery are lower than those of the blank.

②Improve beef quality

Xanthan gum improves the water retention of beef mainly based on two aspects. One is that xanthan gum itself is a hydrocolloid, which penetrates into beef tissue to increase the water retention capacity of muscles; the other is that the water retention of meat can be achieved through the gel-like structure of protein. And electrostatic interaction, among which myosin in the muscle structural protein plays a decisive role in its water retention.

The pH value is an important parameter to measure beef quality. It not only affects the palatability, tenderness, cooking loss and shelf time of beef, but also significantly correlates with beef\’s moisture content, meat color and flavor. When the muscle pH is close to its protein isoelectric point (5.0-5.5), the mechanical strength of the meat is the highest, the tenderness is poor, and the hydraulic power is also low. Production usually requires the pH of meat to deviate from its isoelectric point. Soaking beef with xanthan gum solution can increase the PH value of its muscles. Therefore, adding xanthan gum will help improve the water retention and texture quality of beef.

The maximum shearing force of beef can reflect the tenderness of beef. The smaller the shearing force, the better the tenderness. Therefore, 0.5% xanthan gum infusion can improve the tenderness of beef. The reason may be: Xanthan gum can chelate Ca2+, which may promote the transfer of Ca2+ in muscle cells into sarcoplasm, thereby activating calpain in sarcoplasm, promoting the hydrolysis of muscle protein, resulting in z-line in muscle fiber structure It disintegrates until it disappears, and the sarcomere is broken, myofibrils become small pieces, thereby tenderizing the muscles.

Summary

The aqueous solution of xanthan gum has unique rheological properties—shear thinning. As the shear rate increases, the apparent viscosity of the solution decreases significantly; it has thickening properties and has a greater viscosity at a lower concentration; it has a good Water solubility, stability to heat, acid and alkali, and good compatibility with a variety of salts. These many characteristics enable it to significantly improve the texture, taste, and appearance quality of food by controlling the rheological behavior of the product, and increase its commercial value. Therefore, the application prospect in food is very broad.